- Hits: 535

UDS2-73 SL and TRAM

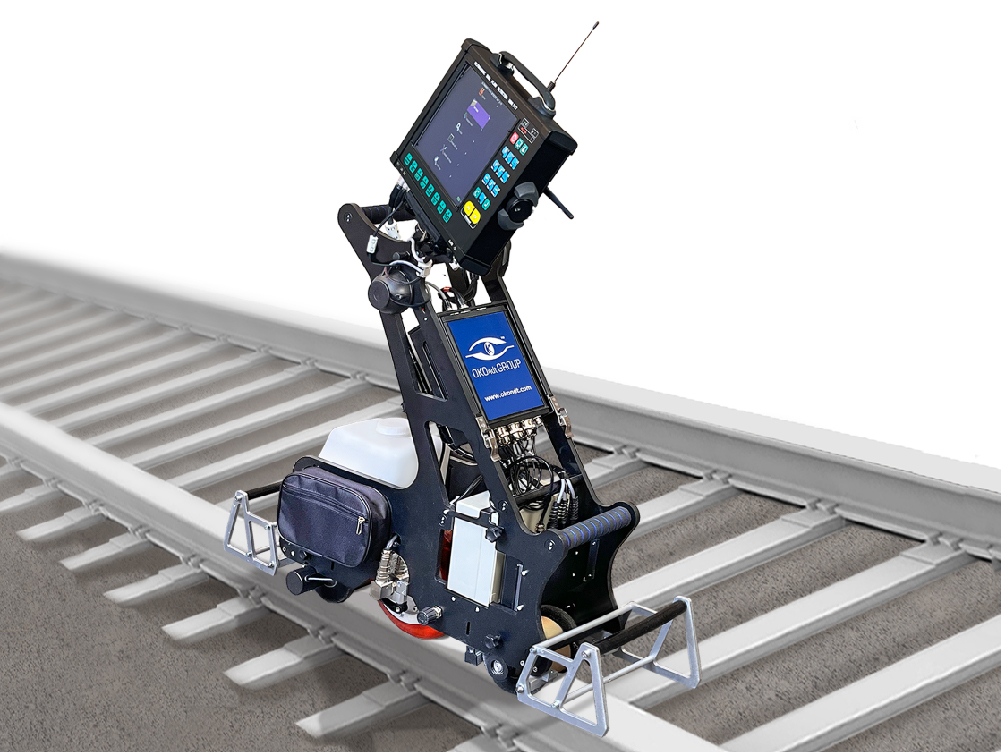

Ultrasonic dual-rail flaw detector UDS2-73 SL for ultrasonic inspection of standard profile rails and tram rails

Ultrasonic dual-rail flaw detector UDS2-73 SL for ultrasonic inspection of standard profile rails and tram rails

OKOSCAN UT 73 HS Pickup is a high-speed ultrasonic testing system for rails with testing speed of up to 40 km/h (24.85 mph) which is installed onto the customer`s vehicle (based on Ford F350 XL (SUPER DUTY) with combined course car.

The UDS2-73 SWP ultrasonic rail flaw detector is designed for continuous, mechanised testing of rail tracks, including turnouts (such as crossings and frogs), at speeds of up to 5 km/h.

The OKOSCAN 73HS System is intended for automated high-speed testing of rail in service.

The Sonocon B belongs to the next generation of portable UT instruments. Using high-end electronics and having the richest set of modes and software features, it can solve any task that can be solved with a portable UT device.

Sonocon BL belongs to the latest generation of portable UT instruments. Using high-end electronics and having the richest set of modes and software features, it can solve any task that can be sold with portable UT.

The UDS2-77 ultrasonic single-rail flaw detector is a hand-push cart intended for inspecting one rail line. The product is manufactured in nine different versions and can be equipped with either a Slide Search Unit or a Search Wheel, both of which are fitted with ultrasonic probes. It can contain between three and 13 UT probes.

USR-01 Set is intended for ultrasonic inspection of aluminothermic welded rail joints in accordance with EN14730-1 requirements. The USR-01 Set can be used for inspection of joints welded by the electrocontact method, for secondary rail track inspection based on the results of mechanized and quick systems of ultrasonic testing, as well as for pre-weld inspection of end sections of new and used rails before welding them at rail welding enterprises or in tracks.

The flaw detector is intended for defect detection on the running surface of both rails and in the rail cross-section, excluding rail base blades. It employs a flaw detection trolley for continuous testing and manual probes for confirmatory testing of individual rail cross-section segments and welded joints.

The ОКО-22М-UT ultrasonic flaw detector is a standalone electronic unit. It is intended for application in high-performance automated multi-channel NDT Systems, transportable systems (mechanized NDT systems) or for manual testing.

Need help?